TBB BUREAU

MUMBAI, SEPT 23, 2021

CSIR-National Chemical Laboratory (CSIR-NCL), Pune jointly with Reliance Industries Ltd. (RIL) and several other companies from Pune have achieved a breakthrough to manufacture useful moulded plastic components from COVID-19 PPE waste.

The successful pilot project has the potential to scale up and replicate throughout the country to convert PPE waste into useful and safe products.

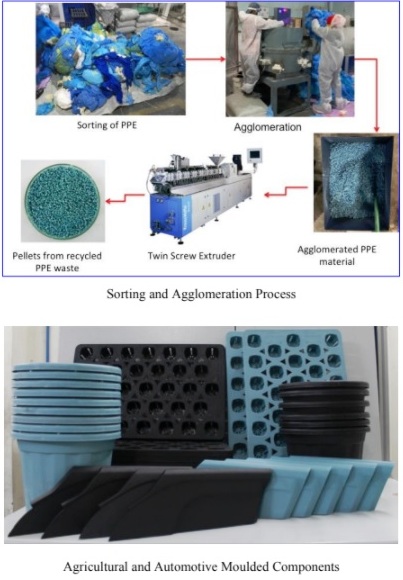

A pilot project converted the decontaminated PPE waste (mainly comprising PPE suits/overalls) into an easily processable and upcycled agglomerated form (pellets or granules). The polymer pellets can find usage in non-food applications, including high-performance automotive components.

A substantial increase in demand for single use plastic items such as Personal Protective Equipment (PPE), masks, gloves, etc. has been observed since the outbreak of COVID-19 pandemic. Across India, more than 200 tons of COVID-19 related waste was generated every day in May 2021. So far, this hazardous PPE waste is incinerated at central waste management (BMWM) facilities. Incineration is energy-intensive and leads to the release of harmful greenhouse gases.

CSIR-NCL, RIL and other companies embarked on a mission to develop an end-to-end process for effective recycling of COVID-19 plastic waste to produce value-added plastic products ensuring decontamination of COVID-19 plastic waste, focusing on the conversion of the plastic waste suitable for downstream processing and identification of potential stakeholders/markets for creating value for entire supply-chain.

In a proof-of-concept study, CSIR-NCL team successfully demonstrated the lab-scale manufacture of moulded automotive products from the decontaminated PPE plastic waste (at Niky Precision Engineers, Pune) by leveraging the existing recycling infrastructure available in Indian cities.

CSIR-NCL and RIL have now signed an MoU to scale up the production to pilot-scale, laying a path to take the concept to the national level.

A pilot scale of 100 Kg in the Pune city area was successfully implemented by collaborating with Pune-based companies, viz. APPL Industries Limited, SKYi Composites, Harsh Deep Agro Products, Urmila Polymers, Jai Hind Autotech Pvt. Ltd., which produced value-added products.

The feed material (PPE kits) was collected and decontaminated by Passco Environmental Solutions, a waste management company located in Pune.

CSIR-NCL secured all regulatory approvals needed from Maharashtra Pollution Control Board (MPCB) to complete this pilot trial.

The technical journey of CSIR-NCL, aided by Reliance and CSIR-Indian Institute of Petroleum (CSIR-IIP) Dehradun, with funding from the Council of Scientific and Industrial Research, mainly involved converting the decontaminated PPE waste (mainly comprising PPE suits/overalls) into an easily processable and upcycled agglomerated form (pellets or granules). It was ensured that the polymer pellets show the right attributes necessary for successful conversion to produce non-food applications, including high-performance automotive components.

This pilot project can be implemented across India to build a sustainable circular “green” economy that can propel India’s growth in this relatively untapped sector and contribute towards India’s socio-environmental targets.

The Business Bytes

The Business Bytes